At Dehnco, we have an unwavering commitment to environmental stewardship, responsible labor practices, and human rights. We uphold the highest ethical standards in all operations, ensuring transparency and integrity. Our dedication to sustainable procurement means we partner only with suppliers who share our values, prioritizing materials and processes that minimize environmental impact and respect workers’ rights. Together, we are building a responsible, sustainable future for all.

I am proud to announce that Dehnco has earned a Platinum Medal, a recognition awarded to the Top 1% of companies assessed worldwide by EcoVadis in the 12 months prior to the medal issue date. It reflects the quality of the company's sustainability management system and demonstrates a commitment to promoting transparency throughout the value chain.

Sincerely,

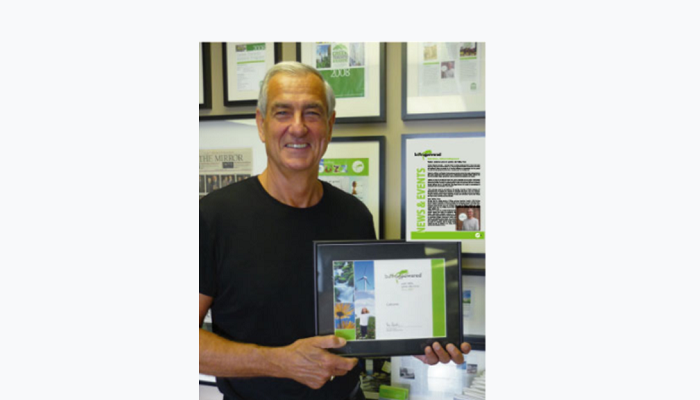

Jeff Dehnert

President

Learn More About Our Environmental Leadership

Our Commitment

We're committed to finding sustainable and eco-conscious solutions that benefit our client, our workers, and the planet.

Environmental Awards

We’re prould of the recognition we have received for our environmental leadership and our commitment to sustainability.

Green Manufacturing

We have made many advances in transitioning each area of our manufacturing process to be an environmentally sensitive process.

Bullfrog Power & Renewable Choice Energy

Dehnco and Calstone are making a difference with renewable energy.

Ponds

Calstone's stormwater management system captures 100% of the rainwater from Calstone’s 3,900 square meter roof.

GREENGUARD

Our manufacturing partner, Calstone, is GREENGUARD certified for providing low-emitting projects.