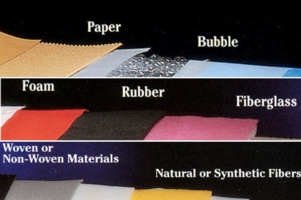

Typical Applications

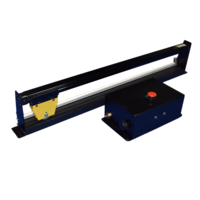

Compression Cutter Technology positions the material between the sharp rotary cutting blade and a flat hardened metal cutting surface in the base.

Sufficient down pressure is automatically exerted against the blade to compress and cleanly cut through materials.

"Dynamic tension" between the upper channel and the base assures uniform cutting compression across the entire cutting surface.

General Specifications

- Compression Cutter Technology is easy to operate and ruggedly constructed for long life.

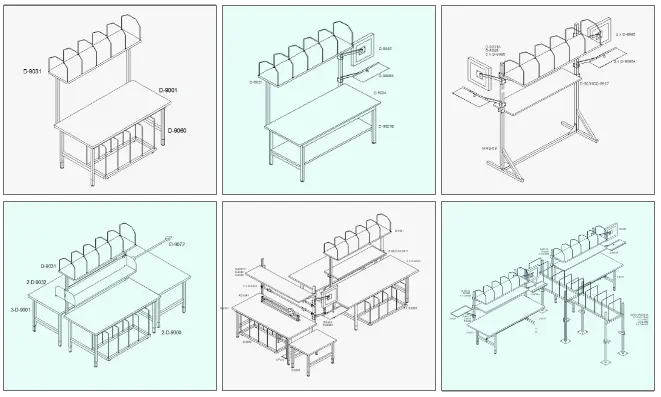

- Compression Cutter Technology can be easily mounted in-line with existing roll storage or can be integrated into any Dehnco table or roll storage system.

- Compression Cutter Technology cuts both directions and has a one year functional guarantee.

- A built-in roller and separator system accommodates and facilitates the dispensing of up to three rolls of material.

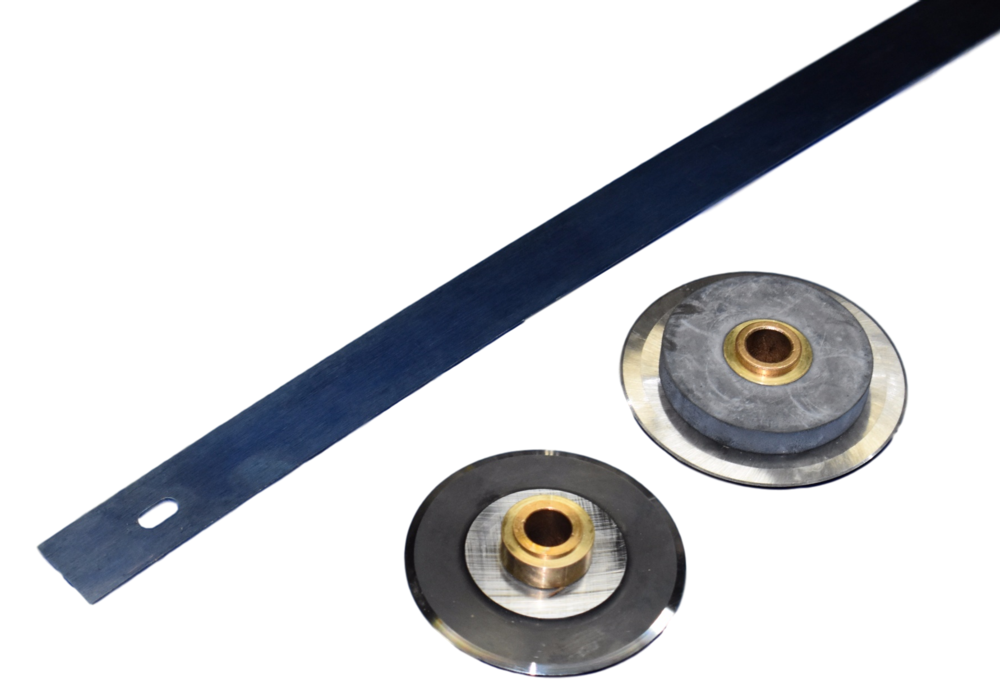

- The Compression Cutter Technology blades are durable, easy to replace and can be sharpened many times.

- Cutters are easy and safe to operate.

- Compression Cutter Technology can be equipped to operate with Dehnco pneumatic drive systems.

- Five sizes are available to cut materials up to 72" wide.

- Special sizeCompression Cutter Technology is available on request.