Typical Applications

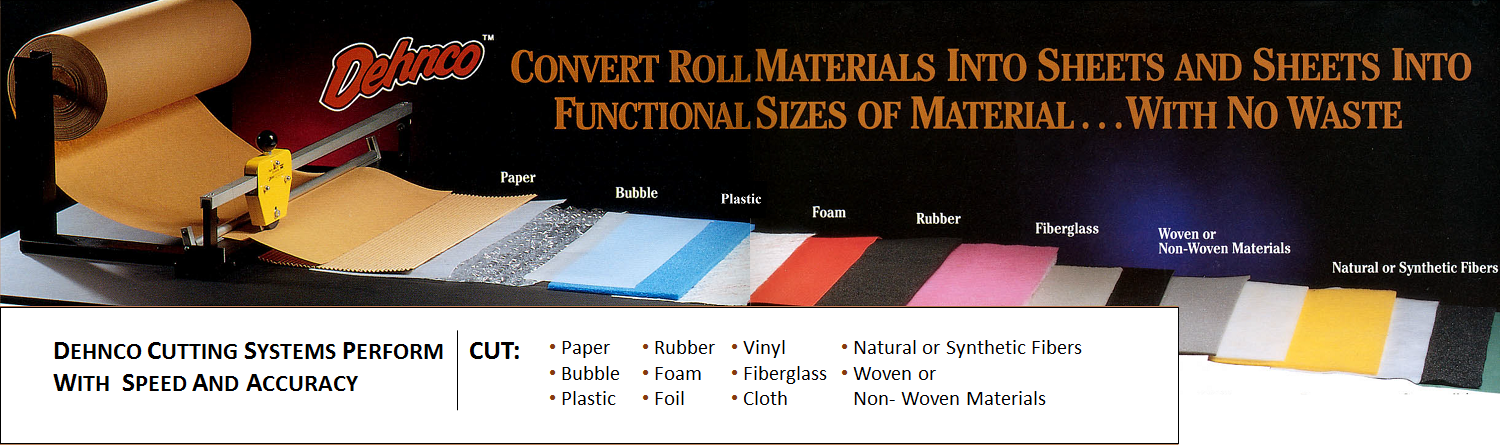

The Insulation Cutter is a fast efficient way to dispense and cut useable size Insulation sheets from rolls of material or cut smaller pieces from large sheets

A Insulation Cutter is used to replace box cutters, scissors, hand tearing or other inefficient forms of converting Insulation material into sheets.

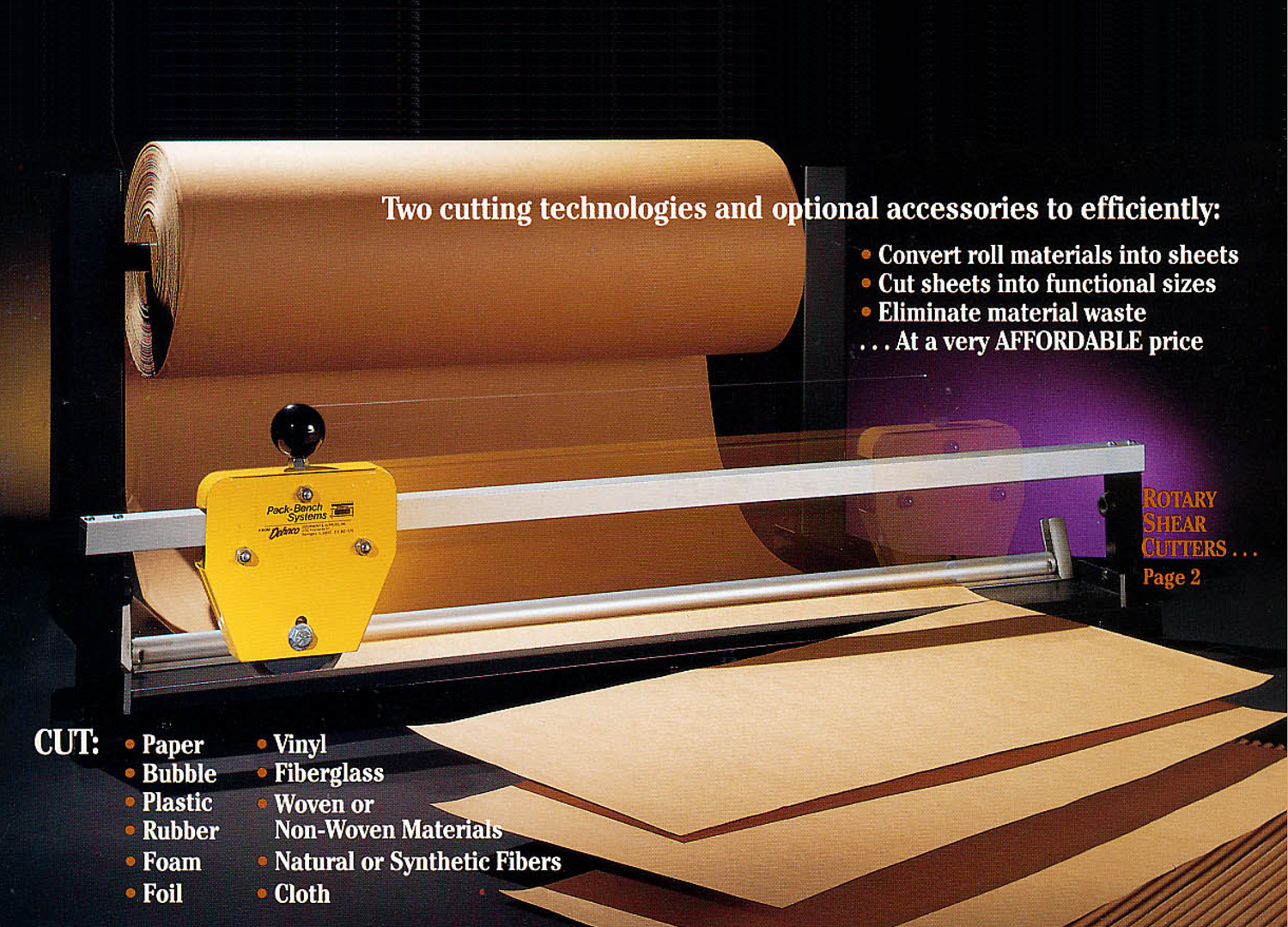

Depending on the type of Insulation, both the compression and rotary shear technology can be used as a Insulation cutter.

Every Insulation Cutter can be supplied with an automatic pneumatic drive attachment or it can be incorporated into a fully automatic sheeting system to increase cutting productivity.

General Specifications

- The Insulation Cutter is easy to operate and ruggedly constructed for long life.

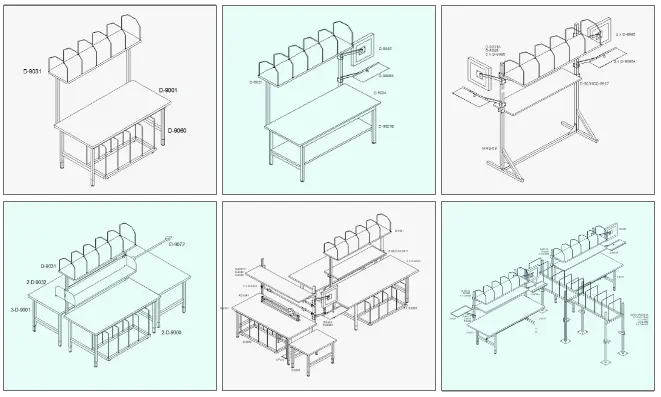

- A Insulation Cutter can be easily mounted in-line with existing roll storage or can be integrated into any Dehnco table or roll storage system.

- The Insulation Cutter cuts both directions and has a one year functional guarantee.

- A built-in roller and separator system accommodates and facilitates the dispensing of up to three rolls of material.

- The Insulation Cutter blade is durable, easy to replace and can be sharpened many times.

- Every Insulation Cutter is easy and safe to operate.

View our Cutter Solutions and Systems for cutting insulation.